It is well known that water vapor in a vacuum chamber presents a unique challenge because of the polar nature of the water molecule. Water likes to stick to surfaces and reside there until it desorbes, only to stick to another surface. This is why the predominant gas load in a chamber at high vacuum pressure (which is approximately between 1×10-3 and 5×10-8 torr) is water vapor.

As one pumps a chamber full of atmospheric gas, gases such as Ar, N2 and O2 are quickly removed. As this happens, the composition of the gas becomes predominately water vapor.

In a production environment, this water partial pressure can lengthen the time it takes to get into production after the chamber has been opened. In a semiconductor fab, where time is money, the faster you get back into production, the faster you can start making product (money).

Benefit may be realized by using cryogenic surfaces that provide auxiliary water vapor pumping. These “water pumps” come in many different forms such as cooled tubes or panels within the system or cryo-cooled baffles in front of other HiVac pumps. The cooling can accomplished with the use of liquid nitrogen or closed loop refrigeration.

The water pumping speed of a cryogenic surface is dependent on the temperature of the surface and the surface area of the cryogenic surface.

Water vapor pumping speed of cryogenic surfaces at constant surface temperature. Lafferty, 1998 ISBN 0-471-17593-5

Below are two different styles of water pumps that can be placed on the inlet stage of a high vacuum pump such as a turbomolecular pump or a diffusion pump.

Two styles of water pumps from Brooks Automation.

Some thought must be used when deciding what type of water pump to use and how to use them.

In chambers that will capture water vapor on a cyclical basis such as a load lock, a considerable amount of frost can build up over time. This frost must be eventually regenerated (sublimated off to rejuvenate the pumping surface). Care must be take while this is done. If the ice is just allowed to melt, it will drip on the chamber floor. This can cause corrosion and particles in sensitive applications.

One method to prevent this is to bring the temperature of the surface up to a moderate temperature and allow the gas to sublimate while under rough vacuum. This can be a lengthy process.

An alternative method is to purge the the chamber with a flow of N2, which may not be practical if the chamber is large.

In critical applications, the water pumping surface is often affixed to the chamber with its own chamber that can be valved off. This can limit the pump speed of the water pump but at least the regeneration can be done as with a cryopump.

Another design consideration is whether or not the water pump can function with the process. For example, having a surface with frost in the same chamber as a plasma process is not workable.

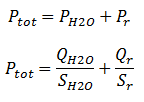

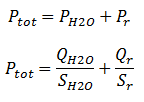

Since we are interested in removing water and what the effect on the system pressure will be, let us break Ptot into two components; PH2O, the partial pressure of water and Pr, the remaining gas that is not water vapor.

Where Qx is the gas load and Sx is the pump speed for each water vapor and residual gases. Quite often one knows the gas load QH2O of the water vapor from a residual gas analysis. Using that one can work out the expected water vapor pump speed and a prediction can be made has to how much the total pressure can be reduced.

In the case when a water pump is used as an appendage pump, meaning that it can be isolated by a gate valve, one must be aware that if there is a partial pressure of water vapor in the system and if the pump is isolated then the water pump speed reduced. The pressure of the system will increase accordingly. For example, suppose there are a cryopanel and a turbomolecular pump in parallel on the chamber the total pump speed for water will be

If one isolates the cryopanel, then one is only left with turbomolecular pump pumping on that water vapor. At the time that the cryopanel is isolated, there is a water vapor gas load at that particular time is QH2O(t). Therefore the resulting pressure will rise accordingly depending on how much cryopanel water pump speed is loss.

This is important to understand, especially if the system engineer is interested in reducing the post maintenance recovery of a tool using water pumps. Many tools such as plasma systems cannot tolerate a water pump in the process environment therefore the water pump is put behind an isolation gate valve. The process engineer must understand that although the target recovery pressure may have been achieved with the use of a water pump that there is still a water gas load, QH2O(t). The water pumping speed SH2O will be reduced to the level of the high vacuum pump and PH2O will increase according to the loss of water pump speed.

I hope that you find this helpful. More useful vacuum technology can be found in the book Understanding Modern Vacuum Technology.